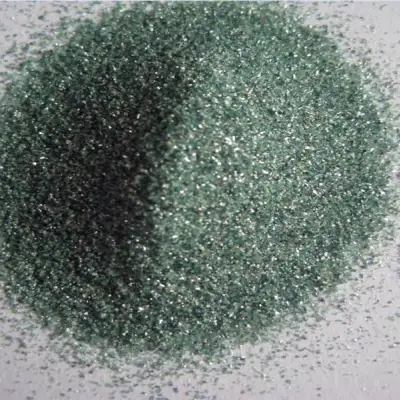

Haixu Abrasives Green Silicon Carbide sand is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. Its hardness is between fused alumina and synthetic diamond. Mechanical intensity of it is higher than fused alumina.it is brittle and sharp and has electrical and heat conductivity in some degree.

|

Haixu Abrasives Green Silicon Carbide sand Physical and Chemical Composition

|

|

|

Physical Properties

|

|

|

Hardness: Knoop

|

2600

|

|

Hardness: Mohs

|

9.4 min

|

|

Melting Point

|

4712°F (2600°C)

|

|

Specific Gravity

|

3.2 g/cm3

|

|

Particle Shape

|

Blocky, Sharp

|

|

Color

|

Green

|

|

Typical Chemical Analysis

|

|

|

Total SiC

|

99.05%

|

|

Total SiO2

|

0.2%

|

|

Total Si

|

0.03%

|

|

Total Fe

|

0.04%

|

|

Total C

|

0.1%

|

|

F-macrogrits sizes bonded

|

|

|

Grit designation

|

Mean diameter in um

|

|

F20

|

1040

|

|

F30

|

625

|

|

F46

|

370

|

|

F60

|

260

|

|

F80

|

185

|

|

F100

|

129

|

|

F120

|

109

|

|

F220

|

58

|

المراجعات

لا توجد مراجعات بعد.